Servo-driven machines from 58Ton to 3300Ton.

No energy wasting because output volume changes by load. Save 30%-80% than tradition fixed pump machines.

01

Servo System

02

Clamping Unit

- Box mould platen design

- 5 pivot vertical double toggle

- Mold thickness adjustment by hydraulic gear

- Precise, low pressure and fast mold adjustment

- Low pressure mold protection

03

Injection Unit

- Optimized injection

- Double cylinder balanced guide

- Multiple stage pressure and speed control

- Back pressure controlled by micro-processor

04

Electricity Components

- World brand components

- Large LCD screen

- Dynamic monitor of machine operation

- 200 sets mold data savable

- Full error alarm system

- Linear displacement transducer controls injection, clamping and ejection.

05

Hydraulic Components

- Fast response hydraulic control

- Pressure and flow proportional valve control

- World branded components

Servo-driven machines from 58Ton to 3300Ton

No energy wasting because output volume changes by load. Save 30%-80% than tradition fixed pump machines.

1

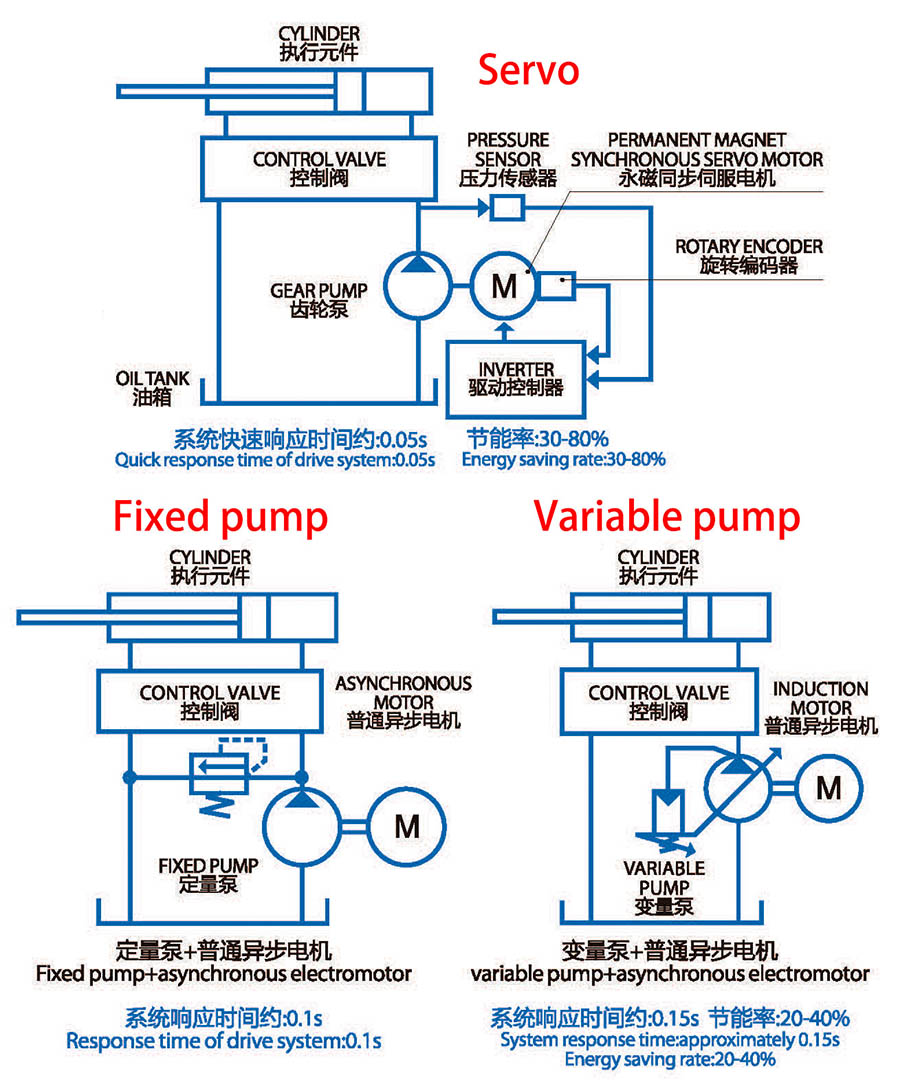

Servo System

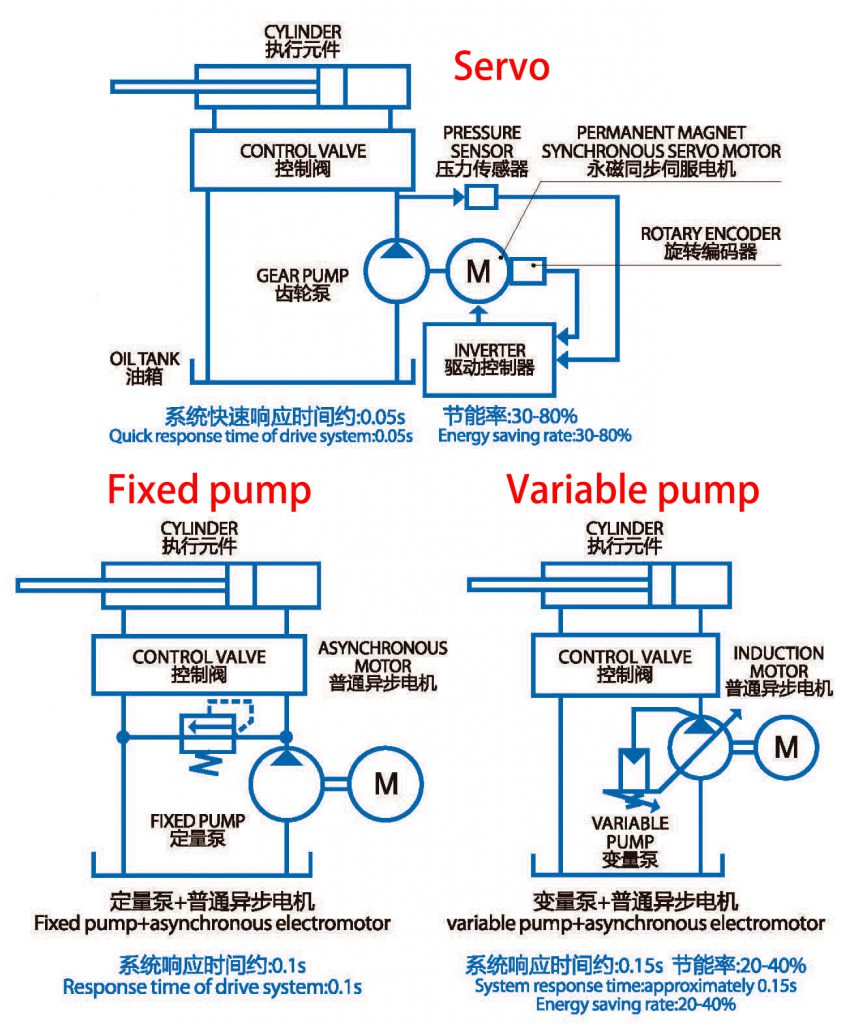

Advantage of servo system

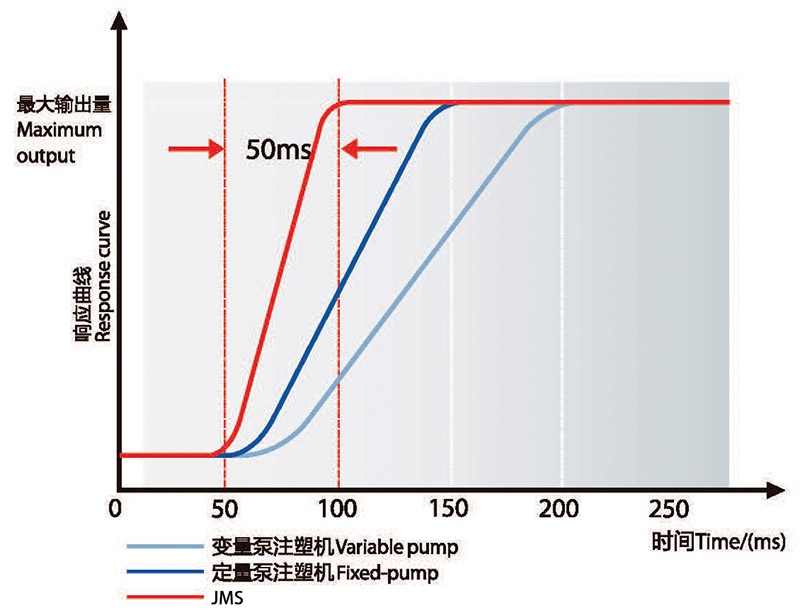

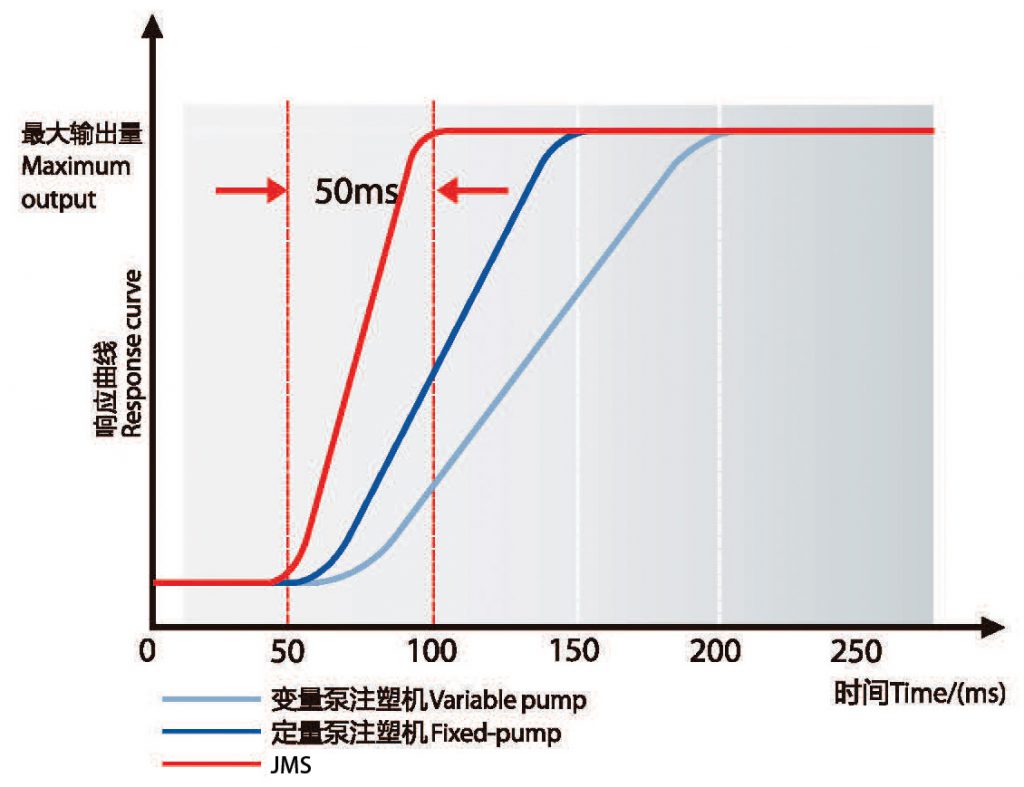

Fast Response shorten cycle time

Fast response time of drive system with 0.05s only to reach the max power output. Cycle time is substantially shortened compared with traditional fixed pump machine.

Fast response time of drive system with 0.05s only to reach the max power output. Cycle time is substantially shortened compared with traditional fixed pump machine.

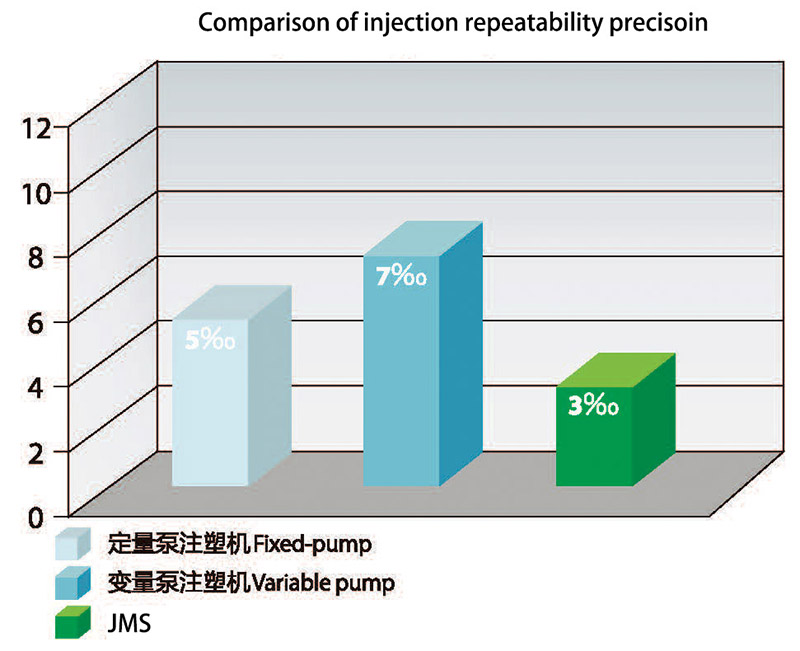

Injection repeatability tolerance

Significantly lower parts failure rate thanks to closed loop control system

Significantly lower parts failure rate thanks to closed loop control system

High performance servo motor

Motor keeps adjusting speed by feedback from sensor to save energy.

Motor keeps adjusting speed by feedback from sensor to save energy.

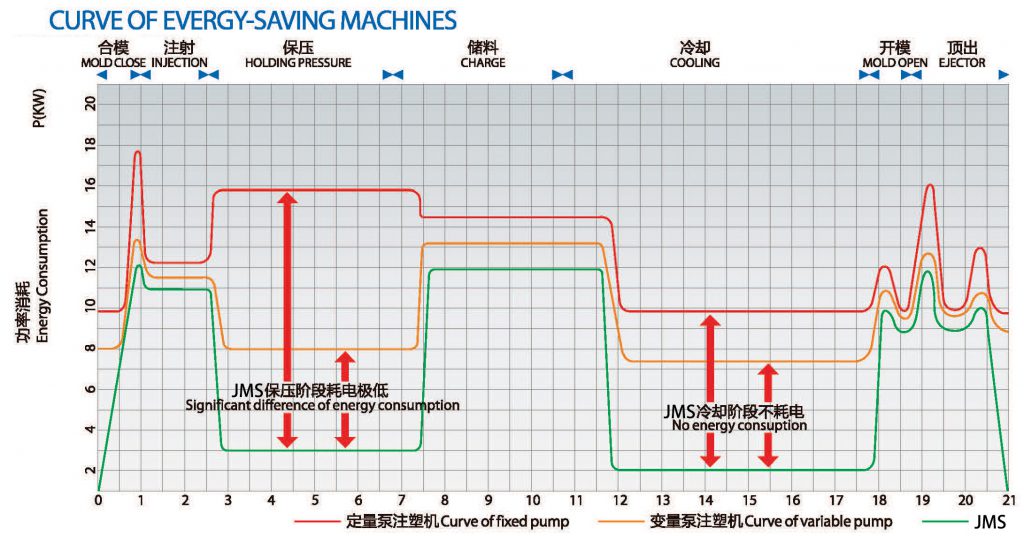

Energy consumption at each stage

2

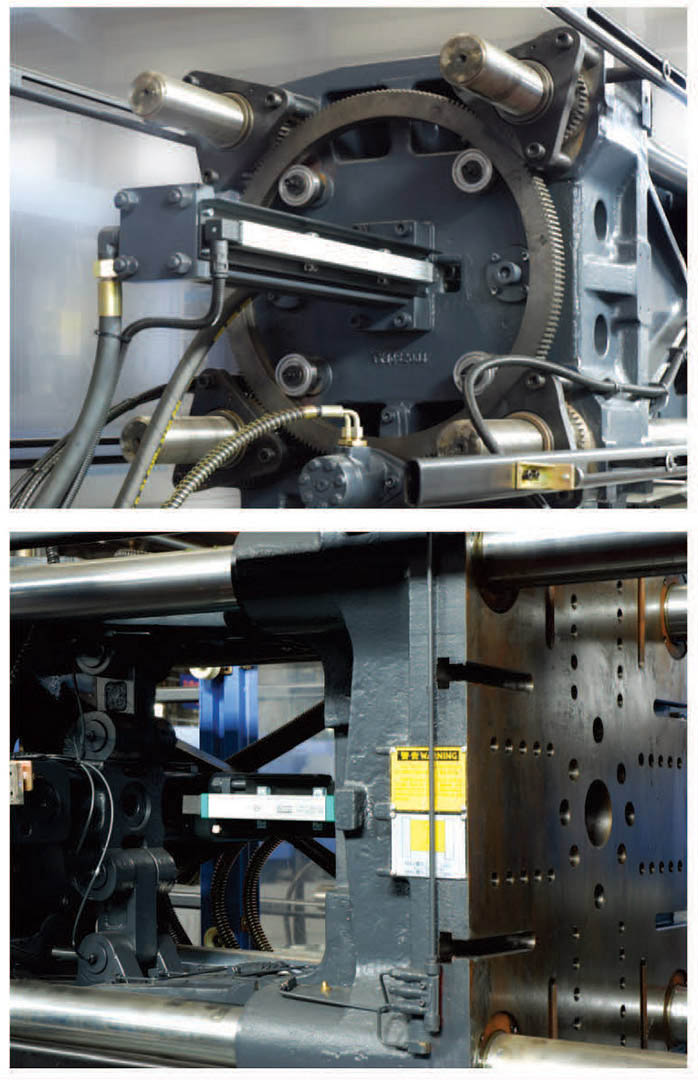

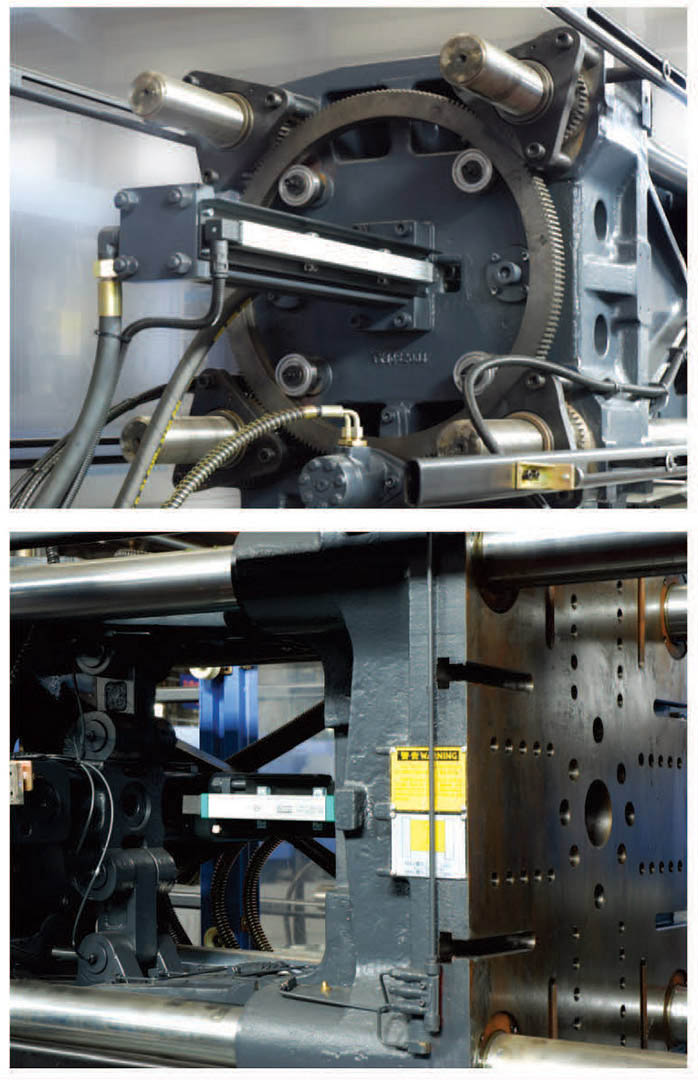

Clamping Unit

- Box mould platen design

- 5 pivot vertical double toggle

- Mold thickness adjustment by hydraulic gear

- Precise, low pressure and fast mold adjustment

- Low pressure mold protection

3

Injection Unit

- Optimized injection

- Double cylinder balanced guide

- Multiple stage pressure and speed control

- Back pressure controlled by micro-processor

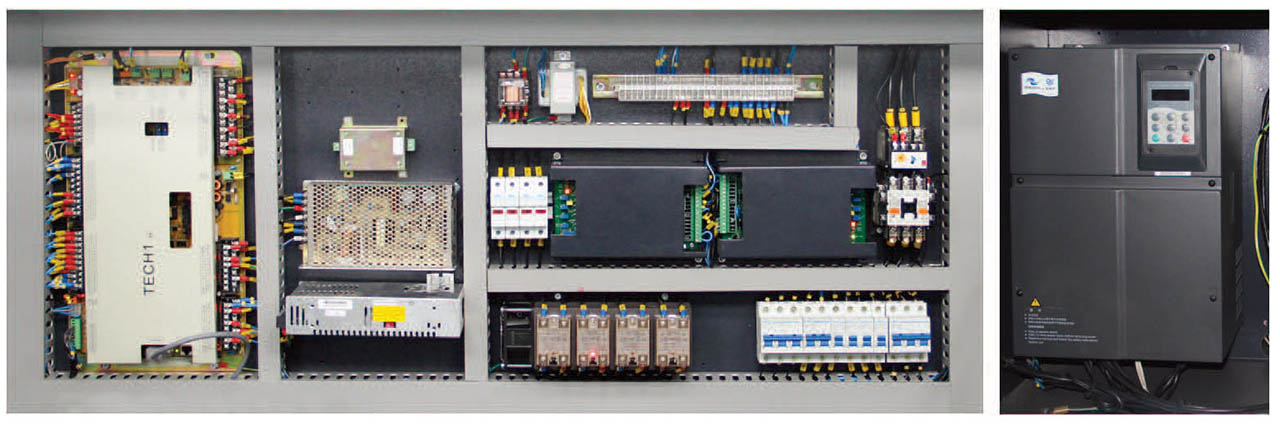

4

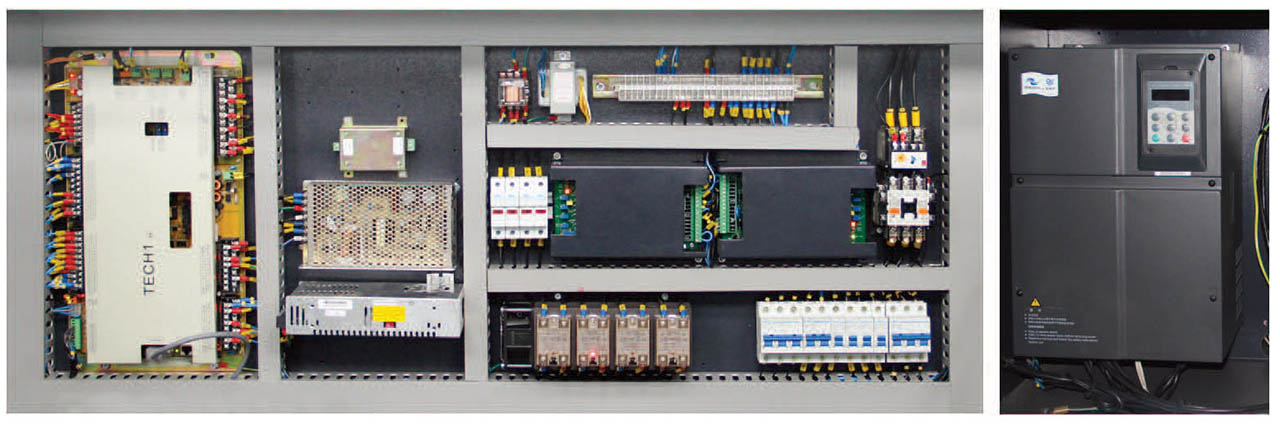

Electricity Components

- World brand components

- Large LCD screen

- Dynamic monitor of machine operation

- 200 sets mold data savable

- Full error alarm system

- Linear displacement transducer controls injection, clamping and ejection.

5

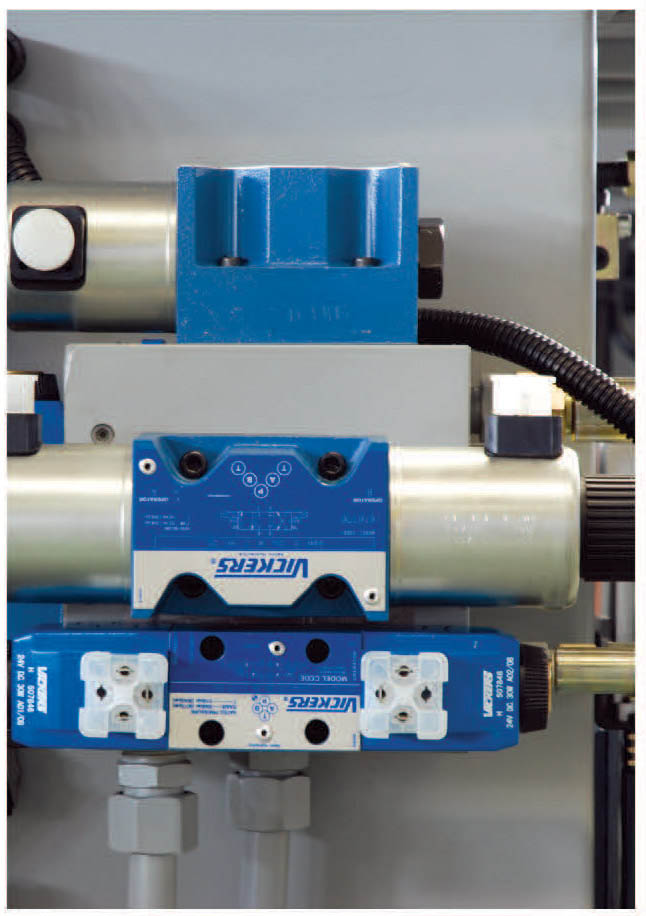

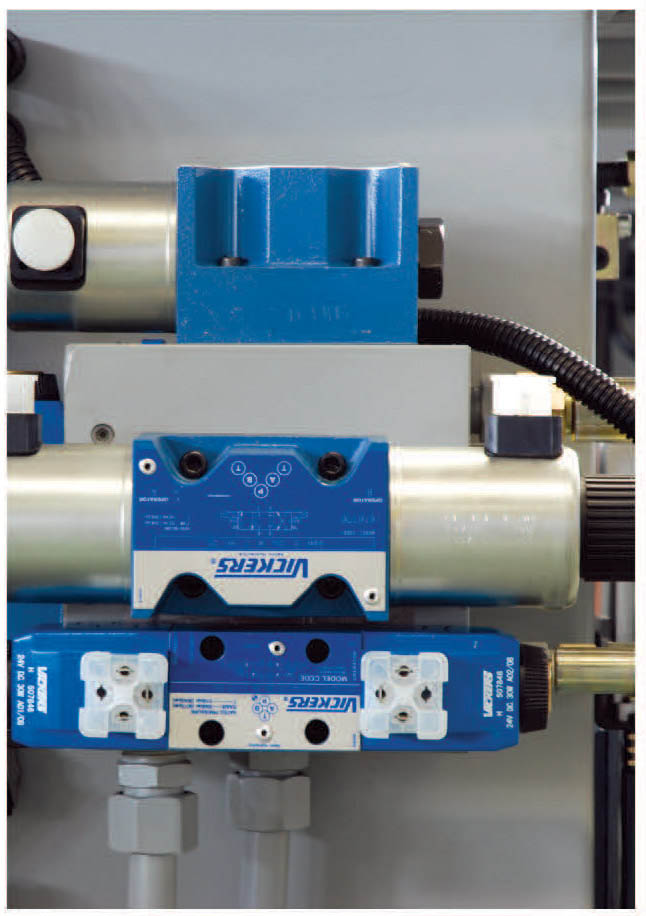

Hydraulic Components

- Fast response hydraulic control

- Pressure and flow proportional valve control

- World branded components